Industrial stainless steel toilets have various flushing options to suit your needs. Aesthetics is not the primary focus but functionality. In most cases companies install a stainless steel toilet due to vandalism and it is also the flush mechanism that suffers. So selecting the right one for the industry is crucial.

There are three basic flush systems available:

- Exposed flush mechanism (This includes cisterns, push button flush systems and IR flush systems)

- Built in wall (Mostly boxed flush systems)

- Duct mechanism (The most vandal proof system and is also used in prisons)

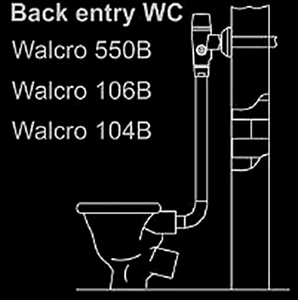

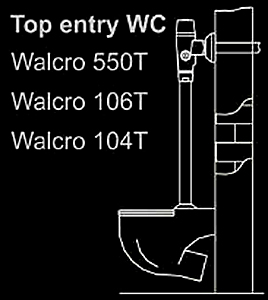

Below are the five installation types found in most industrial installations. We have not included the concealed Geberit types as these are not vandal resistant and we have found that the front flush mechanism tends to be vandalised the most.

Flush mechanism with a cistern

Exposed flush mechanisms

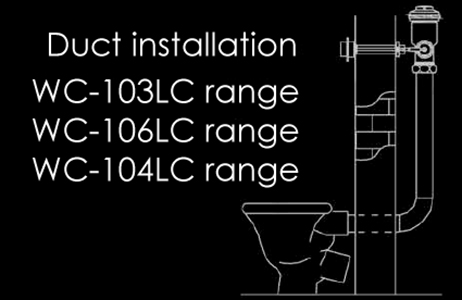

Concealed duct type flush mechanisms

A summary of all the flush valves that can be used for toilets (even slop hoppers and sluice sinks) can be found below. Please visit our store or main site for more detailed information on each valve.

| Feature | Top Entry Exposed | Back Entry Exposed | Concealed/In Wall back entry | Concealed Duct/Prison back entry |

|---|---|---|---|---|

| Low Pressure (0.3-6 bar, 25mm inlet) | 106T 106HT 104T 104HT | 106B 106SB 106HB 104B 104HB | 107C/LP | 106 or 104CXP 106 or 104C 106 or 104C-SS |

| High Pressure (1- 6 bar, 20mm inlet) | 550T 550HT | 550B 550SP 550HB | 107C/HP | 103LCXP 103LC 103LCSS |

2 Comments

how is the cst for the above Flush mechanism

Hi. I have mailed you.